Editor’s note: Lowell Powell, partner to Royal’s Marketing & Outreach Director and Catracha Coffee Founder Mayra Orellana-Powell, is the architect of the Catracha Quality Project and a driver behind many of the coffee processing innovations taking place on the ground in Santa Elena’s coffee community. His essay here was a response to Royal’s Home Roasters Round Table Webinar which took place in April, 2020, near the beginning of a global response to the COVID-19 crisis.

Roasting Alone in the Time of COVID 19

By Lowell Powell

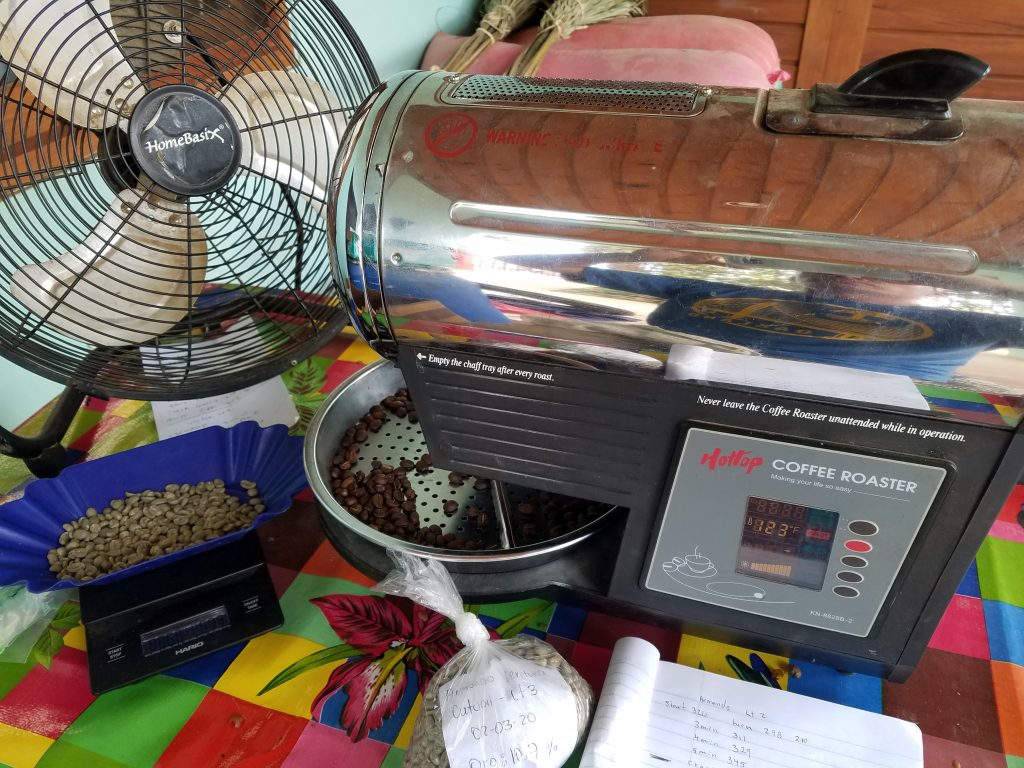

I am the not so public side of Catracha Coffee and also Mayra’s husband. Since 2016, Mayra and I have been living in Santa Elena. I have been busy learning all things coffee from fertilizer to processing. I also roast and cup coffee here in Santa Elena. I have a 25 pound production roaster made in Honduras and two sample roasters, a Behmor and a Hot Top (both gifts passed on from Mayra’s co-workers).

I have been bumping along in a self-learning way. It has not been that hard to pick up the basics mostly because I have been reading the Crown Jewel analysis for Catracha Jewels along the way and had a number of experienced visitors give some helpful tips. But improving my skills in a vacuum has proven unlikely.

With Honduras locked down to control the spread of COVID 19, I started roasting through many samples from the 2020 crops all alone. It has been painfully obvious that my roasting skills have not brought out the best in the coffee. I know what Catracha lots should taste like because every other year I have cupped them with professionals who have done the roasting.

Photo by Lowell Powell

I was frustrated because I had made some positive adjustments early this year. Of the machines I have, I elected to use the Hot Top to roast samples because it basically works like a drum roaster and I can do back to back roasts faster than I can with the Behmor.

Last year I had been set on doing 100 gram batches for no reason other than it seemed like a round number. This year I elected to reduce the batch to 50 grams to get a shorter roast time. Something less than 8 minutes. This batch size works well for me because I am only using two cupping bowls with 10.5 grams per bowl with 190 grams of water.

I also discovered that I could charge the roaster much hotter than the 167 degrees where the the machine starts beeping to prompt you to drop the coffee. Now I ignored the beeping and wait for the roaster to reach 330 before dropping the coffee. To my surprise, after dropping the coffee the temperature dropped and then turned much like the production roaster performs.

Despite these new measures, total roast times and rate of rise were impossible to duplicate from one roast to the next. Even worse, the final product had all the hallmarks of underdevelopment. The weight loss was never more than 11 percent, the beans sounded like gravel in the grinder, smelled like sawdust and the crust in the cup always broke on its own before 4 minutes. I tried for longer development times and only managed to scorch the outside, which only added an ashy component to the coffee profile.

I was aware that these super dense beans could take a lot of heat and I did not want to return to lower heat and longer roasts from prior years where I learned all about the hallmarks of baking coffee.

Luckly, I sat down and watched the home roaster webinar that Candice, Chris and Evan put out recently. And they said some things to put me back on track. The discussions about different machines and sensors and transferring profiles for different machines in combination with charge temperature put me on to something. I heat the Hot Top up as fast as I can to start roasting and then cool it down as fast as I can after roasting to get the machine to begin heating up again. This is a complicated feature of the Hot Top and the Behmor too. Totally different than the production machine where I can drop the roasted coffee and ease the temperature back to my desired charge temperature in just a matter of a minute and then start the next roast, getting the same results from batch to batch.

Charging the Hot Top with full heat and dropping the coffee at the desired charge temperature of 330 was like tossing a ball into an open window of a bullet train as it screamed past. Maybe I was dropping at 330 or maybe 340 or maybe 350. This made the turning point and the roast temperatures wildly unpredictable and almost impossible to create a repeatable roast profile. At the expense of doing things slower, I decide to turn the heat off about 20 degrees before the desired 330 charge temperature and then patiently watched the temperature creep up to 330. Dropping the coffee at the desired charge temperature after this change was like tossing a marble in a big basket tied to a donkey slowly walking past. And from there the turning point and rate of rise were much more manageable.

Candice unlocked the biggest problem relating to underdeveloped roasts when she described the energy in a coffee at crack and the important fix of dropping the temperature just before crack (the U) to control the energy in post crack development. After this adjustment, the coffee developed nicely post crack rather than burning up on the outside and underdeveloped on the inside.

After the webinar I roasted 20 samples and the results on the cupping table were lovely. I went back and read Candice’s Crown analysis on Catracha Jewels and this guidance was there in plain text. I guess I had to hear it first.

FYI, we are at 1830 MASL here in Santa Elena if you want to come and study that elevation question from the webinar after this roasting alone time is all behind us. Thanks again for sharing information. Means a lot to my learning experience here in Santa Elena.